Post-War Expansion to Evendale Campus and the World

In 1945, Formica managers met to decide the company’s future direction, aware that the construction field had been dormant for five years. They recognized the need to intensify efforts after the war to support the remodeling of neglected public buildings, the revival of companies, the production of office furniture, and the construction of new schools, in addition to kitchens, as service members returned home to start families.

By 1946, the company secured its early international expansion through a licensing agreement with British De La Rue, setting up campuses in Europe, Australia, South America, New Zealand, India, and South Africa. Following rapid growth, in 1977, De La Rue sold the Formica entities back to its parent company, American Cyanamid. Concurrently, American Cyanamid managed Formica’s expansion into the emerging markets of Asia. The post-war expansion activities extended the American brand and technology beyond Cincinnati, making Formica a globally recognized material and brand.

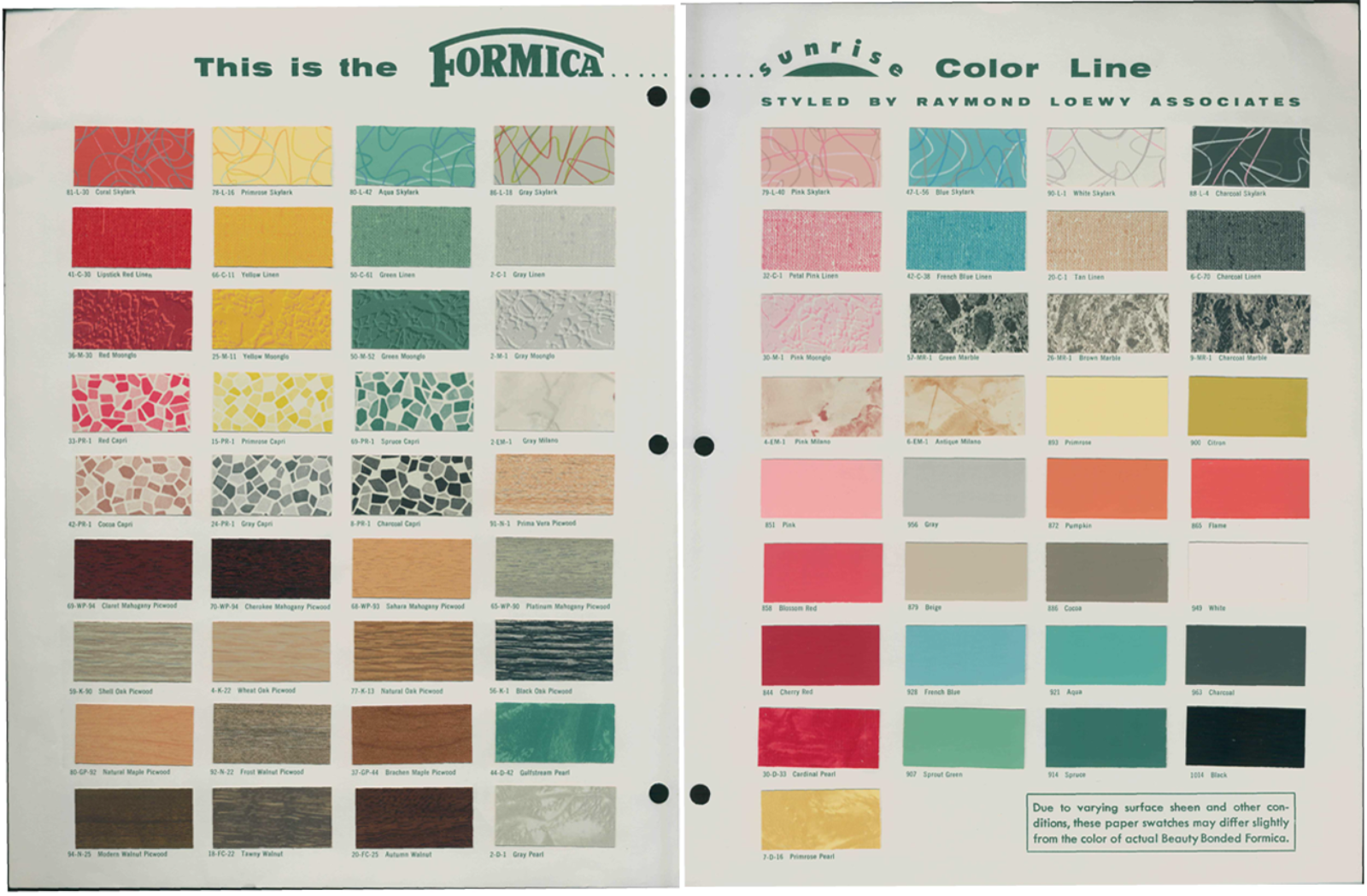

To restart the decorative business, Formica also fortified its laminate ranges by collaborating with prominent modernists of the time. In 1948, the company released the iconic patented design called Moonglo by architect Morris B. Sanders, Jr, who unexpectedly died later that year, cutting the creative collaboration short.