The Texas Instruments Semiconductor Building and headquarters in Dallas, Texas, is an example of a much lesser explored, yet no less historically relevant, corporate research facility from the same era as the well-publicized industrial complexes by Eero Saarinen. In 1958, Texan architects O’Neil Ford with Richard Colley, Arch Swank and Sam Zisman conceived of the massive complex (Fig 1), which typified Ford's daring creativity and stands as what has been considered the most technologically innovative design of his career. The Semiconductor Building serves as a larger artifact of twentieth-century technology, showcasing both advancements in concrete structural design and pioneering breakthroughs in the field of digital electronics.

Texas Instruments Semiconductor Building: A Postwar Concrete Masterpiece

Author

Susan Singh

Tags

Jumping on the bandwagon of the electronics industry’s rapid growth in the mid-1950s, Texas Instruments (TI) ambitiously purchased 300 acres north of downtown Dallas to construct their global headquarters and state-of-the-art semiconductor manufacturing facility. According to the corporation's stated programming requirements, they were specifically seeking:

…a plant symbolic of what we want the organization to be, astute in the application of science in most exacting fields…we shall try to do and do well what others cannot do at all.

At the heart of this new campus, the ownership envisioned the crown jewel to be a single, expansive facility capable of housing laboratory research, manufacturing, and office space dedicated to semiconductor business--all under one contiguous roof. TI grappled with how to portray a corporate image of technological dominance. While aiming to lead the electronics market globally, TI also appeared concerned about connecting with the site’s regional Texas roots and the locally established workforce.

Architect O’Neil Ford was regionally renowned and gathered the strongest team of architects in Texas and consultants to vie for the project. Ford was known for innovative design, consistently exploring inventive materials and construction methods to achieve cost effective results. The TI project would be an opportunity to expand his creative endeavors and vision. To achieve the largest spans required, the design proposal included two notable innovations in concrete: a thin shell roof and a full-height interstitial floor space frame.

For the roof, Ford’s team consulted with the global leader and renowned structural artist Felix Candela to perfect the roof’s execution. Candela was a Spanish-trained architect who was exiled and sought asylum in Mexico after fleeing the Civil War in 1939. During the 1940s Candela became fascinated by novel studies of concrete behavior and forms, leading him to intensively devour readings on the topic. He is considered largely self-taught. Despite not having formal engineering training, or maybe because of it, Candela’s inventive designs stemmed largely from his own creative imagination and the way he intuited the potential of exploiting the hyperbolic paraboloid shape. The form is a mathematically constructed shape that curves in two opposing directions. Structurally, the gradual curvature of the hyperbolic paraboloid naturally distributes stresses evenly, directs loading along the curvatures efficiently, and balances both compressive and tensile forces statically.

Candela made a critical discovery that helped him to construct formwork for the thin shells more easily. A smaller, flatter section of the hyperbolic shape, called a hypar, could be modelled using straight lines without a complicated curvature, yet still retain the benefits of a larger hyperbolic. This insight translated to a wooden formwork that could be constructed more practically from straight wooden boards. He combined and configured four of these hypar components into an overall concave shape creating what he coined the “hypar umbrella.” (Fig 2)

As the most straightforward to construct, the umbrellas found practical application primarily for warehouses and industrial projects. In Mexico these project types typically demanded large, unobstructed spaces, with less aesthetic consideration, and more concern for reducing construction costs per square foot. Ford knew this was a natural fit for TI’s programming needs and contacted Candela about consulting for the roof, knowing he was the most experienced expert globally for this particular roof form. This site and another in collaboration with Ford at the Great Southwest Industrial District nearby in Arlington, Texas represent Candela’s only works on US soil.

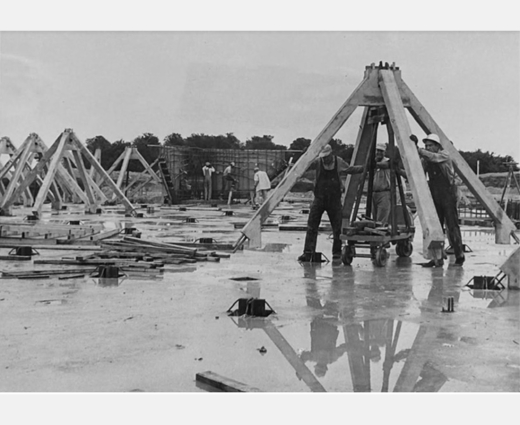

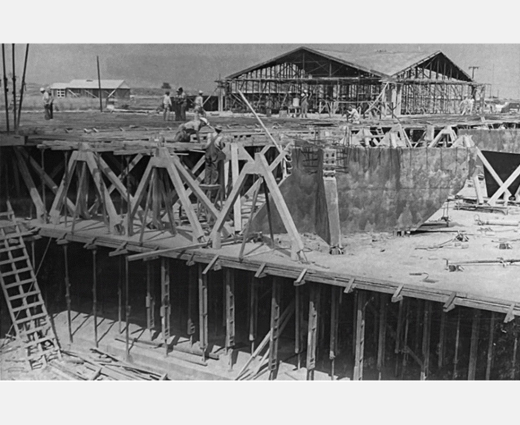

Beyond the roof design, the innovative structural system included a full story interstitial concrete space frame to maintain wide spans on the level below. The second floor contained a unique concrete structure composed of nine-foot high “tetrapods.” Workers assembled these four-legged supports from two separate interlocking pieces created off site. (Fig 3)

Using prefabrication components meant the tetrapods could be cast as interconnectable parts, easily transported to the site on truck beds, and then assembled quickly by laborers. This method would have resulted in substantial cost savings through expedited construction scheduling as well as improving quality assurance of casting the concrete in a controlled environment. In keeping with an effort to minimize costs in constructing such a large structure, modularity and prefabrication of parts was the key to its success.

Given the proposed manufacturing and office operations of the facility, the team proposed a clever solution of creating an entire interstitial floor dedicated to maintenance and servicing of mechanical equipment, utilities and exhaust piping. (Fig 4)

This was especially important given the required flexibility needed for unanticipated growth and change in the electronics industry overall and the manufacturing operations. Here we see an evolution of thought, one which leveraged the structural ability of a space frame to span increasingly larger distances, while integrating it with the building’s utilitarian need for sustainable maintenance and uninterrupted operations. It remains unclear whether the inspiration for the TI space frame was derived from a similar yet shorter solution in steel which the Saarinen father-son duo devised for spanning larger spaces at the GM center just two years prior. Other architects at the time were curiously exploring the advantages of space frames for larger spanning within various contexts. For instance, that same year SOM architect Gertrude Lempp Kerbis experimented with a steel space frame design to create a column-free cafeteria at the US Air Force Academy in Colorado. Here, the full floor version of the concept predates Louis Kahn’s better-known, similar application for the Salk Institute in La Jolla, California.

Both structural advancements were recognized and celebrated by TI. If there are homeowners that are described as “house-proud,” it would be a fair comparison to call the corporation “structure-proud.” At the Semiconductor Building’s inauguration, TI provided a tour of the new plant for more than 9,000 of its employees complete with booklet with maps as well as promotional text and photographs. (Fig 5) What is noteworthy is the imagery of underlying structural elements, both the hypar umbrellas and the tetrapods, were used as visual symbols for the building throughout the pamphlet as well as other promotional materials. This highlights an intriguing aspect of any building’s structure. Underlying structure may or may not be visible or readily apparent to visitors, and in the case of 20th century technological advancements, may require a more deliberate interpretation to recognize technological significance. The obscure nature of “technological craft” in 20th-century structural engineering and construction unfortunately threatens that this history remains confined within the expertise of those within the architectural or engineering fields.

The building would soon become the home of an innovation that would change the future of electronics forever. Just months after opening, employee Jack Kilby unveiled his groundbreaking invention – the integrated circuit, which became a fundamental component of modern semiconductors used in all electronics. Revolutionizing the miniaturization of electronics, Kilby won a Nobel Prize in Physics, the National Medal of Science, and the National Medal of Technology.

Today, the Texas Instruments headquarters and corporate campus continue to serve their original purpose, situated on the same site, albeit with significant expansion. While the Semiconductor Building appears to be centered around semiconductor manufacture, the extent to which the space has been modified over time remains unclear. Unfortunately, given the confidential nature of the operations conducted within, public access to the premises is prohibited. Despite continued private use, it seems to date that no nomination for inclusion on the National Register has been submitted for the Semiconductor Building, recognizing its contribution to building and structural technology history. However, the Texas Historical Commission installed a historic marker at the site in 1988 to commemorate the “Demonstration of the First Working Integrated Circuit.” Today, the Semiconductor Building stands as a physical artifact and symbol of human ingenuity – a novel creation that was representative of its time in the nascent stages of electronics evolution in postwar Texas. Reflecting on this contribution allows us to contextualize the larger continuum of technological advancement in building construction, material, and structural systems.

About the Author

Susan Singh is a Ph.D. Architecture student at the University of Texas Austin, focusing her research on the history of modern building technologies. She is a graduate of the Weitzman Graduate Program in Historic Preservation at the University of Pennsylvania as well as University of Illinois at Urbana-Champaign’s civil engineering program. Her previous professional experience includes construction consulting in Dallas and exterior envelope forensics at several architectural and engineering firms in Chicago and New York. At Penn, her graduate thesis work explored the complexities surrounding the preservation of Philip Johnson’s New York State Pavilion built for the 1964-65 World’s Fair. Her research interest lies at the intersection of the history of construction and building technology and preservation of postwar modernism. She enjoys exploring the origins and evolution of innovation within the modern built environment.